STOP UNNECESSARY REPAIRS, ENSURE TIMELY MAINTENANCE

NO MORE BLIND SPOTS! TAP REAL-TIME VIBRATION INSIGHTS FOR ACCURATE MAINTENANCE DECISIONS

+ 7 %

OPERATIONAL EQUIPMENT EFFICIENCY

- 4 %

ENERGY CONSUMPTION

+ 5 %

ROI PER LINE

NO MORE TECHNICAL JARGON OR CONFUSING REPORTS!

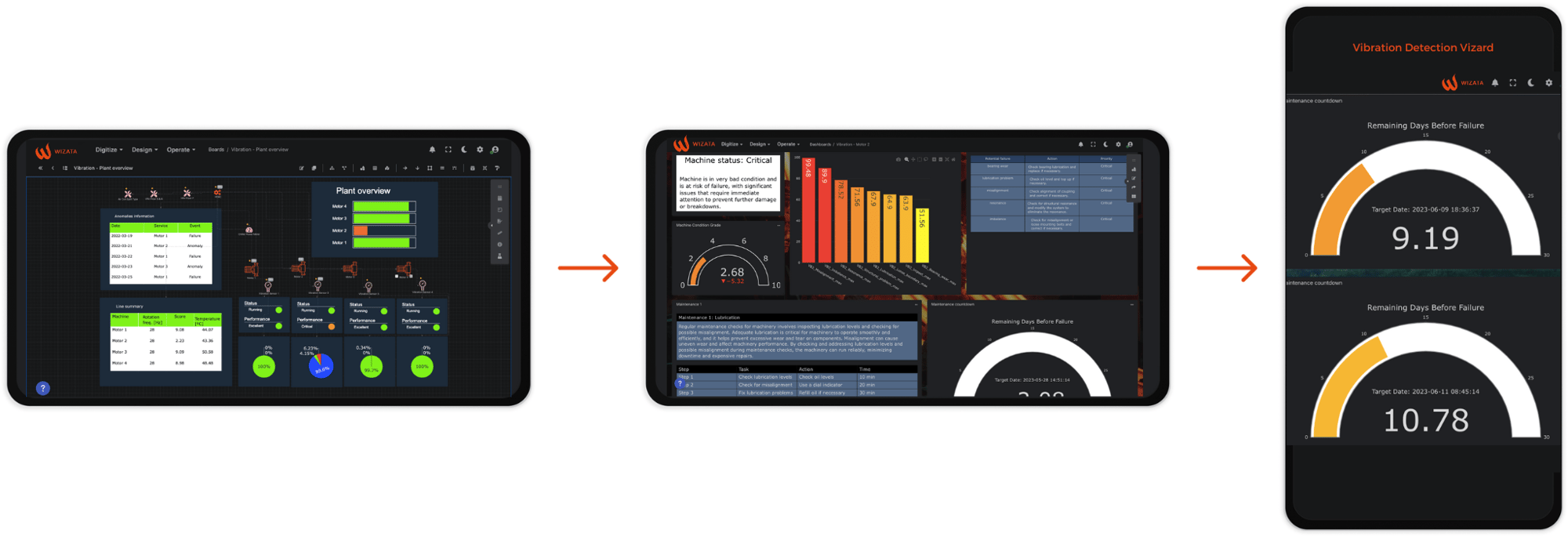

Your new colleague, Wizata's vibration detection wizard is with you.

Wizata is the first tool to bring process engineers and AI together in a seamless experience. Its vibration detection wizard

- Transforms complex data into actionable intelligence

- Optimizes maintenance scheduling to tackle issues before they even know they exist

- Cost-Cutting Maintenance: No more guessing, only action when needed!

By converting raw vibration data into a language tailored to your understanding, you'll bypass the need for technical interpretation.

This means you can swiftly access and comprehend the health status of your assets without any middle steps. Armed with this knowledge, you'll have the power to make informed decisions and take proactive maintenance actions. Maximize efficiency, minimize downtime, and unleash the true potential of your assets!

HOW DOES IT WORK?

START TRIAL

DISCOVER YOUR HIDDEN ANOMALIES TODAY

After trial pricing starts at 2.500 EUR / month.

YOU CAN SEE WHAT WE'VE DONE

“We decided to work with Wizata because they have a better business knowledge of process manufacturing than the competition and their collaborative approach allows us to stay in control of our IP ”

“The AI expertise of Wizata combined with the skills of our engineers allowed us to identify significant opportunities of yield improvement in one of our facilities.”

"A proprietary tool will be cheaper than the Wizata platform and sufficient for a very simplistic use, but as soon as you want to do something with this data in real-time it is either impossible or expensive and with a lot of intermediaries and therefore a risk of bugs which increases beyond reason."